The powder metallurgy processing equipment employed is specifically designed to accurately simulate an industrial press-sinter-size sequence. Research is completed at all stages of the process including powder blending, compaction (uni-axial die and CIP), controlled atmosphere sintering, sizing/repressing, and secondary operations (heat treatment, shot peening, etc.).

Powder Compaction

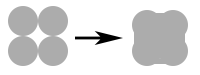

Uni-axial Die Compaction of Powders

- Instron Model 200HVL

- Load Capacity = 1MN

- Maximum Pressure = 600MPa

- Self Contained Tool Sets Available for the Uni-Axial Die Compaction of:

- Discs (15mm, 30mm and 50mm OD)

- Transverse Rupture Strength Bars (12.7 x 31.7mm)

- Charpy Bars (12.7mm x 75mm)

- Rectangular Bars (20 x 90mm)

- Dog Bone Tensile Bars

Universal test frame and the self-contained tooling utilized to simulate industrial powder compaction operations.

Cold Isostatic Press (CIP)

- Avure Technologies

- Maximum Pressure = 415MPa

- Chamber Volume = 3500cm3

Avure Technolgies model LCIP 42260 cold isostatic press for compacting metal powders.

Controlled Atmosphere Sintering

Tube Furnace

- Lindberg Three-Zone Furnace

- Carbolite Three-Zone Furnace

- Stainless Steel Retort with Water Jacketed Cooling Section

- Atmospheres: Ar, N2, Mechanical Vacuum (10-2 Torr)

Customized tandem furnace assembly for sintering PM compacts under a controlled atmosphere.

Bell Jar Furnace

- Materials Research Furnaces

- Maximum Temperature = 1650°C

- Atmospheres: Ar, N2, H2, Mixed Gas, High Vacuum (10-5 Torr)

- Oxygen Monitor

Multi-atmosphere bell jar furnace regularly utilized in sintering studies on a variety of different alloys (aluminum, nickel, iron, titanium, etc.).

Spark Plasma Sintering Furnace

- GT-Advanced Technologies

- Maximum Temperature = 2200°C

- Maximum Load = 100kN

- Atmospheres: Ar, N2, H2, Mixed Gas, Mechanical Vacuum (10-2 Torr)

- 20mm and 40mm OD graphite tooling

Spark plasma sintering furnace utilized to consolidate metallic, ceramic, and composite particulate materials.