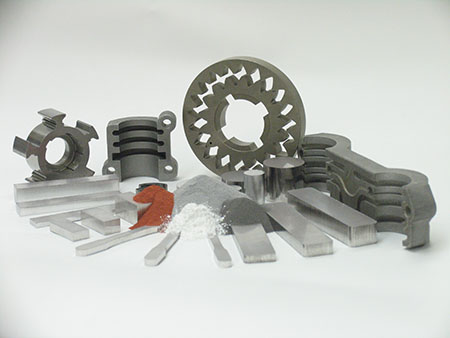

Dr. Bishop’s research program is designed around the development, production, and consolidation of innovative metal powders into finished engineered products. Principal areas of research include the development of advanced light metal alloys and composites for commercial deployment within powder metallurgy (PM) and additive manufacturing (AM) technologies, thermal-mechanical working of sintered preforms, development of alloys with enhanced thermal properties, low-cost materials for AM, and detailed characterization of the microstructure and mechanical properties these innovative materials. Such endeavors are completed for a host of end-use sectors but are principally centered on the automotive, aerospace, and defense industries. His program is underpinned by a vertically integrated suite of advanced research infrastructure that includes in-house capabilities for gas atomization, powder characterization, AM (laser powder bed, directed energy deposition, binder jet printing), PM (press-sinter, sinter-forge, spark plasma sintering), secondary processing (heat treatment, shot peening), and material characterization (microstructure analysis, mechanical testing, residual stress measurement, etc.). The facility itself was jointly funded by the Canadian Foundation for Innovation, the Nova Scotia Research and Innovation Trust Fund, the Faculty of Engineering at Dalhousie University, and long-standing industrial partner GKN Sinter Metals LLC. It is a unique research entity within Atlantic Canada that is staffed by a dedicated, experienced, and hard-working team of engineers, post-doctoral fellows, and graduate students willing and able to tackle challenging initiatives rooted in AM and PM technologies alike.

- Dr. Paul Bishop