The group is equipped to conduct research on three types of additive manufacturing technologies utilized for metallic materials. Namely, metal powder bed fusion, directed energy deposition, and binder jetting.

Metal Powder Bed Fusion (MPBF)

- AconityUS Inc.: Model AconityMINI

- 400W Yb Fiber Laser Operable in Continuous Wave and Pulse Mode

- Variable laser spot size (50 to 400μm)

- Atmospheres: Inert Gas (Ar, N2, He) and Vacuum

- Build Chamber Volumes: 3 Liter and 0.2 Liter

- Heated Build Plate (Tmax = 500°C)

- Processes Reactive (Al, Ti, etc.) and Non-Reactive (Fe, Ni, etc.) Alloys

AconityMINI metal powder bed fusion system.

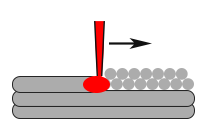

Directed Energy Deposition (DED)

- Optomec Incorporated Model 500 MTS-CA

- Controlled Inert Gas Atmosphere (Ar, N2, He; <10 ppm O2)

- 5 Axis Motion Control

- 80 Liter Build Volume

- 1kW Fiber Laser

- Processes Reactive (Al, Ti, etc.) and Non-Reactive (Fe, Ni, etc.) Alloys, Composites (MMCs/Cermets), Functionally Graded Materials

Optomec 500 MTS-CA system.

Binder Jet Printer

- ExOne Model Innovent+ with Ultrasonic Recoater

- 0.7 Liter Build Volume

- Processes Non-Reactive (Fe, Ni, etc.) Alloys, Composites (MMCs/Cermets), and Ceramics

ExOne Innovent+ binder jet printer.